Manufacturing

Manufacturing ERP System

A comprehensive ERP solution for manufacturing companies, integrating production planning, inventory management, and quality control.

Technologies Used

Python

PostgreSQL

Node.js

AWS

Client

Global Manufacturing Co.

Project Duration

12 months

Completion Date

February 2024

Team Size

8 members

Project Overview

Developed a full-featured ERP system specifically designed for manufacturing operations, focusing on production efficiency and quality control.

Key Features

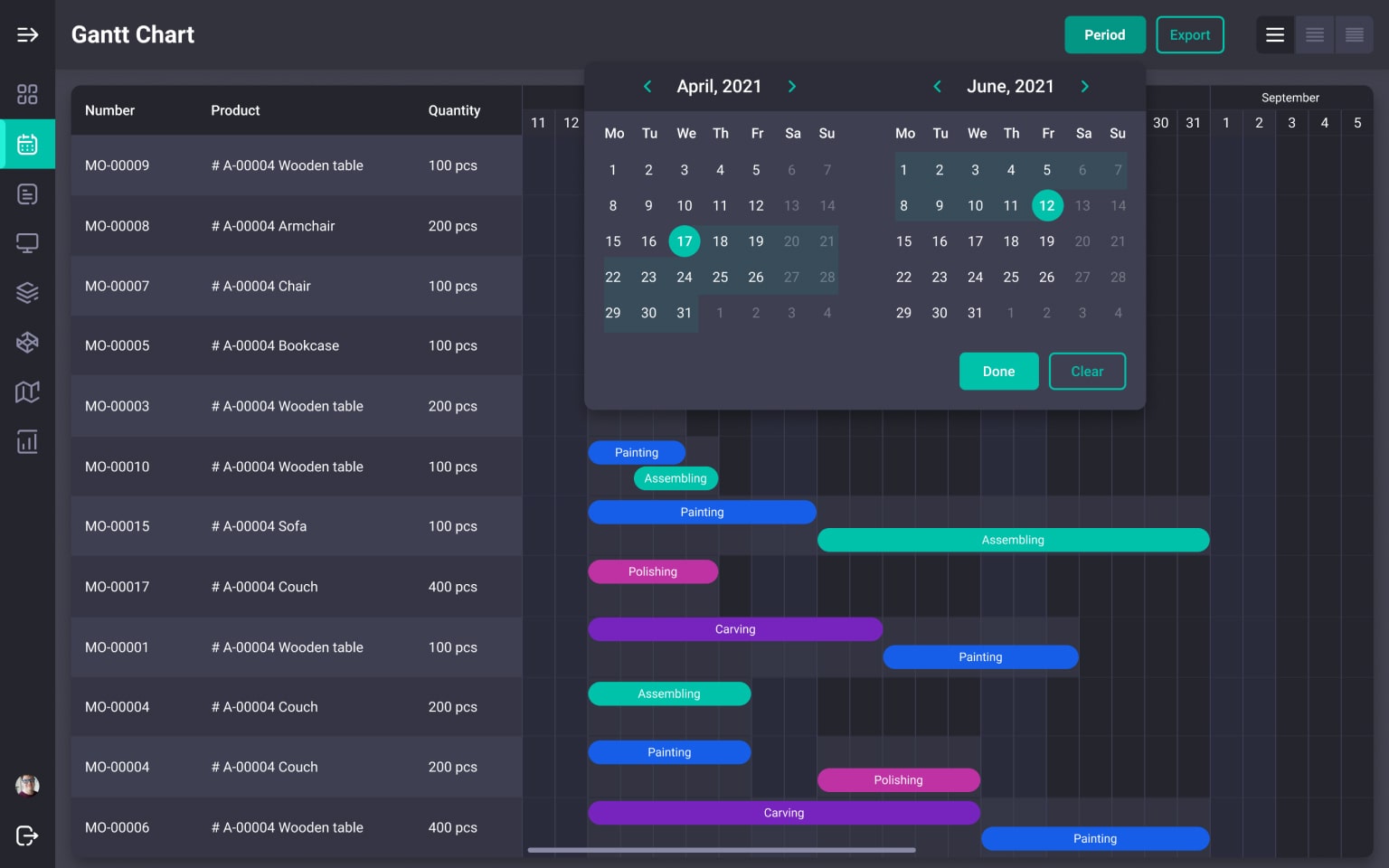

- Real-time production monitoring and scheduling

- Inventory management with automated reordering

- Quality control and compliance tracking

- Resource allocation and capacity planning

- Integration with existing manufacturing equipment

Technical Implementation

The system was built using a microservices architecture to ensure scalability and maintainability. Key technical aspects include:

- Real-time data processing using Apache Kafka

- Containerized deployment with Docker and Kubernetes

- RESTful APIs for system integration

- Advanced analytics and reporting capabilities

Results

- 30% reduction in production downtime

- 25% improvement in inventory accuracy

- 40% faster order processing

- 15% reduction in operational costs